Investors · partners

Why Trinix?

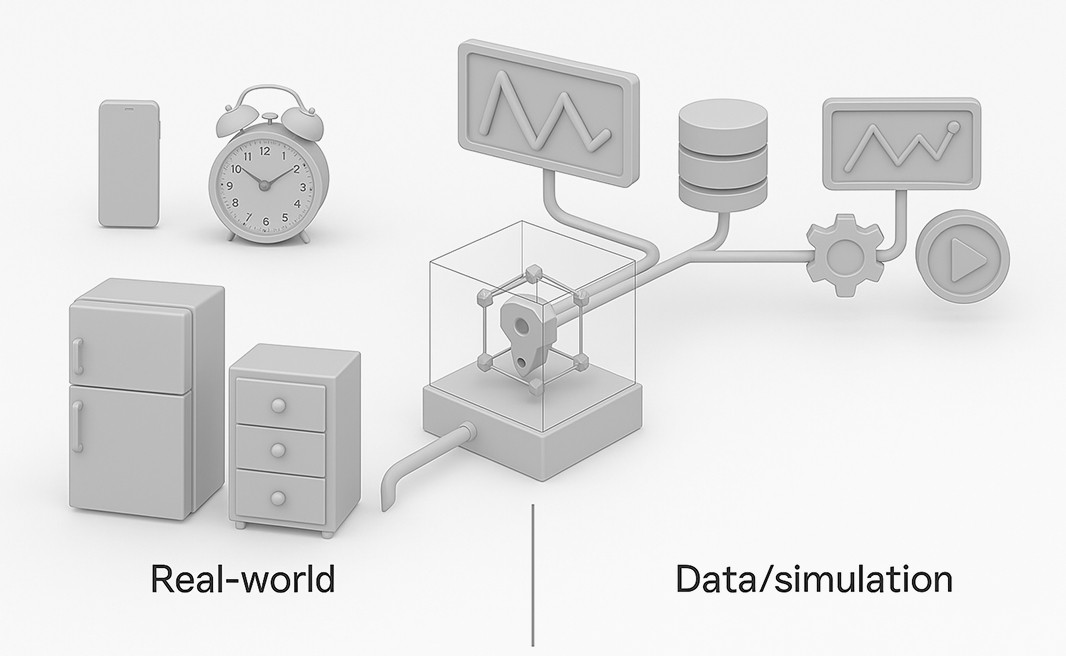

When Data Becomes the Bottleneck

Modern AI systems require vast amounts of diverse and high-fidelity data — yet collecting real-world 3D data is slow, costly, and often incomplete.

Manual CAD modeling doesn’t scale. Existing real-to-simulation methods often lack the diversity and control required for high-fidelity training — mainly due to cost and time limitations.

Scaling 3D Creation for the Age of Industrial AI

Key Advantages

Scalability

Rapid generation across object categories

Cost-efficiency

Jitter removal and parts segmentation are required

Hyper-realism

Physically accurate rendering and formats

Multi-modal output

CAD + Image + Video + Articulation formats

(STEP, GLB, STL, OBJ, MJCF, URDF)

Plug-and-play

with MuJoCo, Omniverse Isaac Sim, Unreal

Core Capabilities

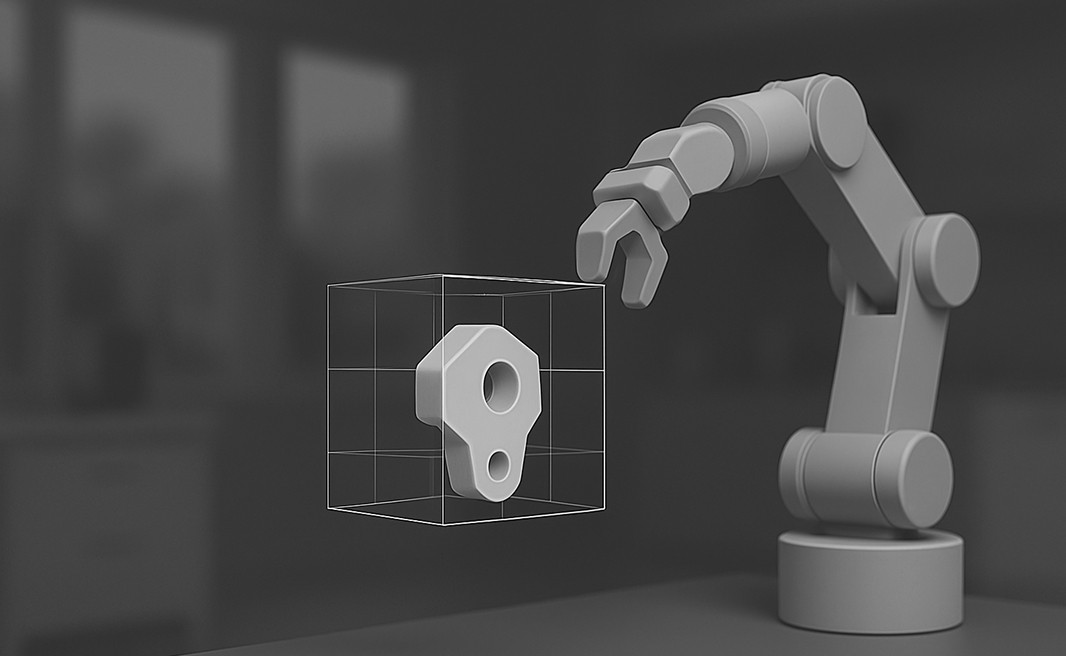

Image to CAD with precise editing for jitter-free, segmented part generation

Smartphone CAD Generation

Physics Simulation: Articulated Objects

Drawer/door/fridge simulation with

step-wise control logic

Dataset Generation for logistics, manipulation, segmentation

Environment randomization and physics-based item handling

Export-ready for NVIDIA Omniverse, MuJoCo, Unreal, Solidworks

3D-based deformation + defect image generation